Bimetal production from Steel Work

A unique patented technology provides high-quality wear-resistance of production equipment.

Start with a technical audit of your business.

Get a questionnaire

A unique patented technology provides high-quality wear-resistance of production equipment.

Start with a technical audit of your business.

Get a questionnaire

The main specialization of the company is the execution of works on the protection of industrial equipment from harmful and destructive factors at the enterprises of the mining, metal, cement, coal, chemical, energy industries and port facilities.

Technical audit of the enterprise and analysis of problem sites of the enterprise

Manufacturing, delivery and installation of bimetal sheets SWIP

Restoration and repair of equipment with the use of wear-resistant materials

Turnkey repair and restoration work on production sites

Welded, surfacing works, metal fabrication of any complexity

Monitoring, control of work and technical maintenance of equipment

During work with production equipment, an integrated approach is important, and that is why we use the whole range of work to achieve the set task: from technical audit to services of the Laboratory of Metal Technology.

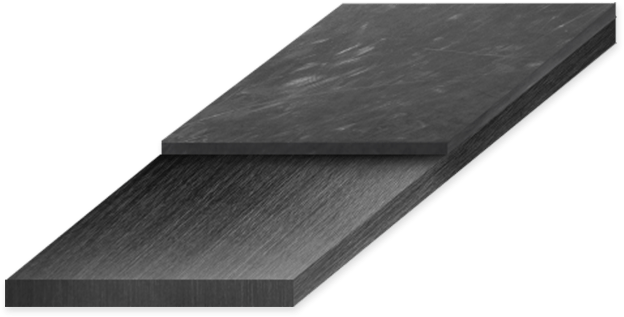

Steel Work Innovation Plate - is a two-layer metallic material that composes an integral part. The sheet consists of two different metals, which can be steel and its alloys, firmly interconnected throughout the contacting.

The company has its own patented technology and a line for the production of SWIP bimetal plates and bimetal products.

GET A QUESTIONNAIRE

takes on mechanical stress

performs a protective function

The advantage of a two-layer metal is the possibility of production of end products of almost any shape, taking into account rolling and bending. Assembling, joining and fixing bimetal products on the protected surface is performed either by welding or by bolting, studs, etc.

Protection of equipment against any type of wear

Increase of equipment service life by 4 times

Lining weight reduction up to 50%

Reduced maintenance and repair costs

Reducing operating costs for equipment maintenance

Lower production costs

Increased equipment performance

No long-time production downtimes

No need to purchase new equipment

SWIP sheets application areas are very different. This material allows enterprises to protect production equipment or equipment for engineering maintenance that has been subjected to wear and needs to be extended.

Mining industry

Steelmaking industry

Cement industry

Coal mining industry

Chemical industry

Electric-power industry

Port facilities

For 12 years of its existence, the company has gained invaluable experience in the field of increasing the resource of process equipment and has established itself as a reliable partner. Expert knowledge and skills of specialists of the company allowed our customers to make production more efficient and successful.

Installation of elements of the aspiration system made of bimetal SWIP sheets at Cherepovets

The repair period increased

Installation of elements of the aspiration system made of bimetal SWIP sheets at Cherepovets

The repair period increased

We entered the international market very quickly by using advanced technologies and latest scientific developments in our activity. Today, our customers are located in more than 10 countries around the world, and we constantly develop the geography.

Click the button below and our specialist will contact you.

Contact the expert

за заполненную форму!