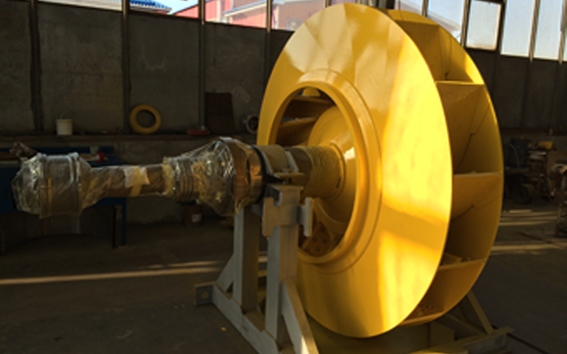

FABRICATING OF WELDED INDUCED DRAFT (ID) FANS

The core business of Steel Work LLC is designing, fabricating, maintenance and repair of Induced Draft ID fans. Steel Work LLC is ready to present a new marketing product: ID fans for sintering manufacturing.

In July 2014 Steel Work LLC fabricated its first ID fan.

Please note: to replace or repair riveted ID fan we need to stop the machine for several hours or days what inflicts severely the productivity of sintering, open-hearth or convertor processes.

To replace the obsolescent fan structures of H-7500 and H-6500 ones, Steel Work LLC has developed a welded structure of ID fan with central toothed disk and blades protected with replaceable linings. The absence of the central disk on the way of the dust flow coming from opposite sides leads to its even distribution over the surface subject to be worn. Therefore we achieve much more even wear of operating surfaces and correspondently we achieve longer servicing life of pieces.

We are proud to have been involving qualified engineers from E.O.Paton Electric Welding Institute to estimate durability, select material, develop new welding technology, etc.

Advantages of a new model of ID fan of Steel Work LLC manufacturing:

- The central disk has the toothed shaped preventing the wear.

- Gas-abrasive flows comes towards each other and become balanced decreasing the lining wear of 2.5-4 times (depending the dust fracture).

- Availability of replaceable hardfaced blade linings doesn’t demand to replace the blades themselves and the central disks, and you needn’t to disable (to damage integrity) the operating wheel.

- Implementing of replaceable blade linings made of hardfaced SWIP® plates efforts you to increase overhaul period as much as 4 times.

- Designed structure of ID fan efforts you to decrease repairs as less as 4 times.

- Designed structure of ID fan efforts you to decrease the possibility to be injured as less as 4 times while performing work of heightened danger.